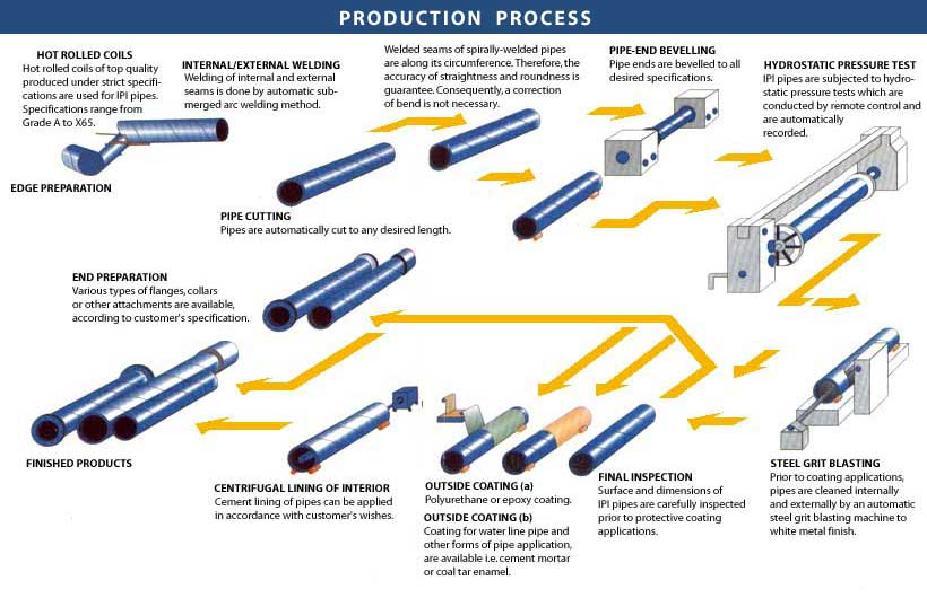

PRODUCTION PROCESS

The main product line of IPI are its spiral-welded steel pipes and fittings. IPI’s four (4) production lines can manufacture spiral welded steel pipe ranging from 100mm to 3,600mm diameter, with wall thickness off 3.4mm to 25mm and pipes of up to 50 meters in length.

IPI pipes are manufactured and provided with protective coating and/or lining against corrosion per clients requirements. For outside surface protection, the pipes are reinforced with cement mortar coating, or weight coating for submarine pipeline, or coal tar enamel with thermo-glass outer wrap, and polyurethane and epoxy coating. For internal protection – cement and epoxy linings. are used for internal protection.

Finished products are most economically transported by barge since the plant is located along Marikina river. Deliveries can also be made by land to any point in Luzon, or by ship to other ports all over the Philippine archipelago.

The spacious plant site provides for extensive manufacturing and storage of finished product, resulting to minimal damages during storage.

.jpg)